- Key Takeaways

- Understanding Manual Handling Risks

- Legal Obligations for Employers

- The TILE Approach to Risk Assessment

- Step-by-Step Guide to Conducting a Manual Handling Risk Assessment

- Common Risk Factors in Manual Handling

- Implementing Control Measures

- Training and Education

- Monitoring and Reviewing Risk Assessments

- Addressing High-Risk Handling Operations

- Reporting and Investigating Incidents

- Summary

- Frequently Asked Questions

A manual handling risk assessment is essential to identify and minimise risks related to lifting, carrying, and other physical tasks. It prevents workplace injuries and ensures compliance with legal requirements. This article explains what manual handling risks are, the legal obligations for employers, assessment methods, and practical safety measures.

Key Takeaways

- Manual handling risks can cause significant injuries, particularly in high-risk sectors; employers must identify and mitigate these risks, as mandated by the Manual Handling Operations Regulations (MHOR) 1992.

- Employers have a legal obligation to optimise worker safety through thorough risk assessments of manual handling tasks involving employee consultation and adherence to structured safety measures.

- The TILE approach—assessing Task, Individual, Load, and Environment—provides a comprehensive framework for identifying and reducing manual handling risks effectively.

Understanding Manual Handling Risks

The Manual Handling Operations Regulations 1992 defines manual handling as any activity involving the transport or support of a load through hand contact or physical force. Such activities include various forms like lifting, lowering, pushing, pulling and carrying. Significant risks associated with manual handling are prevalent in sectors known for their high risks, such as healthcare, agriculture, manufacturing, and construction, due to frequent involvement in tasks that could lead to musculoskeletal disorders—the most common injuries resulting from these types of operations.

Often, these tasks result in injuries caused by poor lifting methods, repetitive actions, or the load being too heavy or unwieldy.

Factors such as monotonous movements and suboptimal working conditions can heighten the chances of injury even when dealing with lighter loads.

Manual handling contributes significantly to over one-third of all reported work-related ill health cases each year.

Typical instances involve:

- Lifting

- Carrying

- Pushing

- Pulling

These scenarios can induce strain-based injuries, among other muscle/bone-related disorders, if not managed properly.

It is incumbent upon employers to recognise and mitigate these hazards diligently. By understanding key factors behind incidents linked to manual handling operations, they can create more robust preventative protocols against them. Circumventing hazardous manual handling endeavours is an important primary intervention according to MHOR directives. Yet when avoidance isn’t feasible, executing comprehensive assessments stands vital for shielding workers from detrimental outcomes.

Legal Obligations for Employers

Employers have a critical legal responsibility to protect the health and safety of their workers, with particular attention given to manual handling tasks. Under the Manual Handling Operations Regulations (MHOR) 1992, it is incumbent upon employers to steer clear of hazardous manual handling operations where possible. This stands as the foremost action they need to undertake. When these risks cannot be avoided altogether, it’s necessary for employers to introduce control measures aimed at diminishing the risk associated with such tasks as much as possible.

The obligation extends beyond mere caution. Conducting comprehensive risk assessments on manual handling is mandated by law. Such evaluations are essential when there is an introduction of new equipment, substances or methods that may spawn fresh hazards. If an organisation employs five or more individuals, documenting these risk assessment results becomes imperative—providing a detailed account regarding pinpointed risks along with strategies employed for their mitigation.

In ensuring compliance with legal standards and fostering workplace safety, involving employees who carry out manual handling jobs in discussions can uncover hidden dangers not immediately obvious from management perspectives. According to legislation, all personnel involved in manual labour receive adequate training in safe handling procedures.

Through a commitment to this structured process set forth by MHOR—assembling tiers of precautionary controls—employers play a pivotal role in decreasing instances related to illness due to work engagements and bolstering overall protection within employment environments.

The TILE Approach to Risk Assessment

Employing the TILE method is crucial for conducting thorough risk assessments in manual handling. This acronym encapsulates four essential aspects that need to be considered: Task, Individual, Load, and Environment. These elements are integral in spotting and lessening risks associated with manual handling by providing a structured framework for ensuring safety.

Delving into each aspect of TILE reveals particular risk factors that could lead to injuries if not properly managed. A close examination of the task at hand, individual abilities, the nature of the load involved, and environmental conditions allows us to perform a detailed assessment. Such scrutiny helps identify specific dangers and organise measures aimed at mitigating these risks effectively.

We will now proceed to delve deeper into each one of these components individually.

Task

Assessing the specifics of a manual handling task is crucial in pinpointing potential hazards. The risk of injury escalates with tasks that involve repetitive actions, including lifting, carrying, pushing and pulling, due to increased fatigue and physical stress on the body. As an example, for repeated lifting activities, it’s recommended that weights be lowered by 30% if lifting occurs 1-2 times per minute. Reduce by half when it happens 5-8 times per minute. And decrease by up to 80% for more than a dozen lifts within the same time frame. Attention should be given to any task demanding bending or twisting movements or those performed at high speeds, as these factors significantly elevate the risks associated with injuries.

Recognising what each manual handling task demands allows employers to strategically prioritise interventions by implementing various control measures designed specifically for such risks. By accurately identifying which tasks come with greater dangers, appropriate protective strategies can be set in motion – whether through using suitable equipment, arranging team-based approaches toward handling materials or altering the nature of tasks themselves, all geared towards safeguarding workers against incidents resulting from manual labour activities.

Individual

Before initiating manual handling tasks, it is imperative to evaluate the capabilities of each individual in order to maintain workplace safety. Such an assessment should factor in distinctive characteristics including one’s fitness level and existing health conditions. Psychological elements like stress due to workload and the interplay of communication within teams must be considered when conducting a risk assessment for manual handling.

For instance, an employee with a history of back problems may need tailored support or modifications made to their assigned tasks.

A thorough evaluation encompasses both physical stature and mental state, assuring that all potential risks are efficiently controlled. Providing a more detailed assessment which aligns specific tasks with individual capacities can significantly diminish the injury hazard and heighten overall security measures in any given workplace setting.

Load

Assessing the attributes of a load is essential in manual handling risk assessments. Factors such as weight, size, shape, temperature and whether the load is steady or likely to shift must be taken into account. For instance, an awkwardly shaped object that may slip out of grasp or one that could move unexpectedly increases the risk of injury.

Carefully considering these elements enables employers to ascertain the most secure practices for managing various loads. Strategies might include deploying special equipment to aid in handling, modifying the load’s physical characteristics for easier management or implementing team handling approaches which distribute work among workers and minimise individual strain from manual labour tasks.

Environment

Environmental conditions are a crucial aspect of safety during manual handling operations. During risk assessments, it is vital to account for environmental factors such as the stability of floors, appropriate ventilation, and adequate lighting conditions. Specifically, inadequate lighting or unsteady flooring surfaces can heighten the difficulty of performing manual handling tasks and elevate the risk of sustaining an injury.

By evaluating the working environment for possible dangers that could impact manual handling activities, we can pinpoint potential hazards. Remedying problems like insufficient illumination or ensuring stable floor conditions contributes to establishing a more secure workplace while diminishing the chance of mishaps related to manual handling.

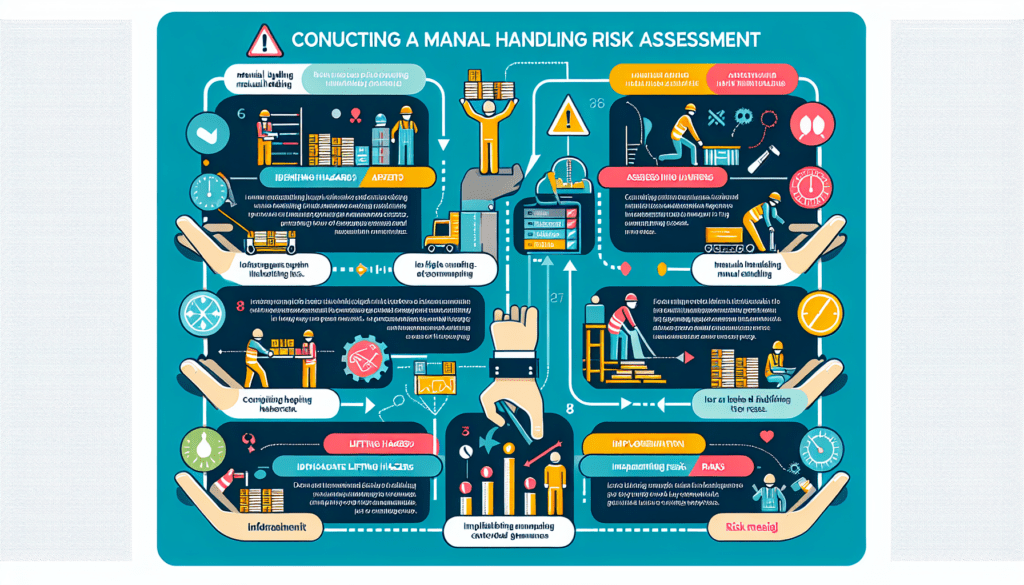

Step-by-Step Guide to Conducting a Manual Handling Risk Assessment

Implementing a manual handling risk assessment is an essential process that comprises multiple critical steps. Initially, it’s vital to pinpoint tasks that potentially carry a manual handling risk of causing injury by consulting with individuals responsible for and those who will perform the task. This results in an in-depth comprehension of the activity involved. To evaluate potential dangers effectively, employing the TILE method proves indispensable after hazards have been recognised. This helps assess various elements like individual capabilities, load features, and environmental factors.

Following the identification of risks through careful analysis, it’s necessary to devise and document measures aimed at mitigating these identified risks adequately. Employers ought to contemplate upgrades within workplace conditions, such as enhancing spatial arrangements or lighting quality, so as to curtail the perils associated with manual handling operations. For persons presenting particular requirements, specialised assessments are warranted in order to address their distinctive circumstances concerning manually handled loads.

The importance lies not only in devising but also in assiduously monitoring how safety procedures are applied post-risk assessments—making sure appropriate practices and tools are consistently employed throughout processes involving material manipulation by hand is key. It falls upon organisations not merely to initiate these evaluations but also renew them frequently—adjustment frequency might range from quarterly reviews or even monthly inspections determined by unique enterprise-related exposure levels toward operational mishaps—to preserve current knowledge about prevalent hazards with an eye toward persistent enhancement of precautionary methods thus diminishing any likelihoods related to sustaining injuries on account of manual endeavours.

Common Risk Factors in Manual Handling

Multiple risk factors exist that can escalate the chances of sustaining an injury while performing manual handling tasks. Examples include improper posture, which heightens the potential for disorders affecting the back, neck, and shoulders. Repetitive actions involved in carrying or lifting items on a frequent basis may cause conditions such as tendonitis due to ongoing strain exerted on muscles and joints.

The presence of environmental dangers Enhances risks associated with manual handling. Slips, trips, and falls stand out among typical hazards leading to a range of injuries including musculoskeletal disorders. Factors like obstructions along transit routes, inadequately serviced equipment, and limited space amplify both difficulty and risk when it comes to executing manual handling duties.

It’s critical to recognise these contributing factors in order to mitigate injury risks effectively — this is pivotal not only for safeguarding against harm but also vital for promoting safety within the workplace environment overall.

Implementing Control Measures

It is essential to enact control measures to reduce the risks associated with manual handling. The adoption of mechanical devices such as hoists, conveyors, and trolleys can lessen the physical demands on employees and lower the chances of sustaining injuries. An example would be arranging stationary heavy items within a workspace so that they remain in one place, minimising the necessity for their manual relocation.

Involving delivery firms that provide staff trained in safe lifting techniques along with proper lifting apparatuses for transporting cumbersome equipment also aids in lessening potential dangers.

Such implementations are instrumental in fostering a safer working atmosphere while safeguarding workers from injuries resulting from manual handling tasks.

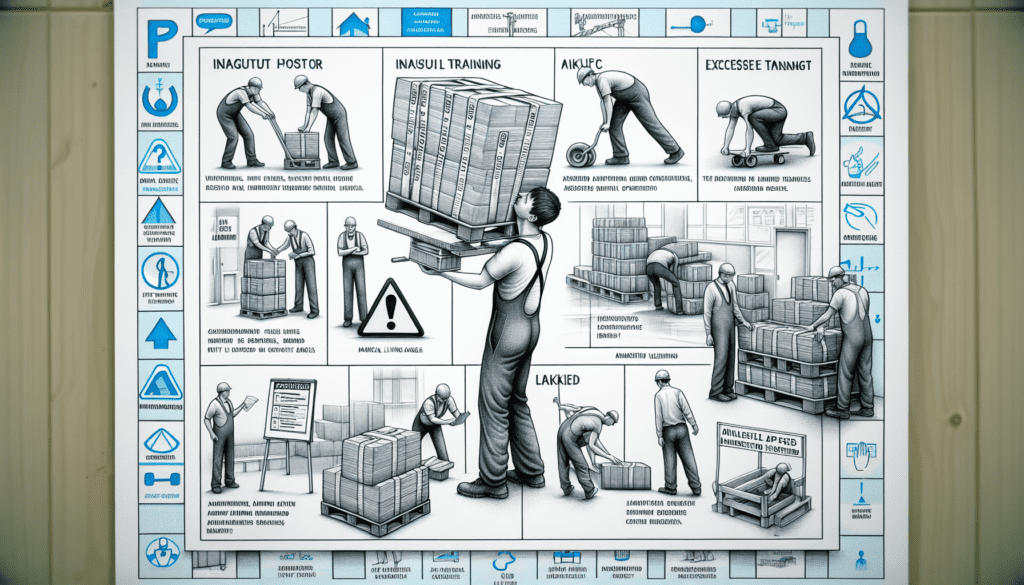

Training and Education

Education and training play a crucial role in managing the risk associated with manual handling. Through proper training, employees learn how to safely utilise equipment, which is essential for reducing the likelihood of developing musculoskeletal disorders. Courses in this field include instruction on safe techniques for lifting, pushing, pulling, and storing items to foster practices that are secure when it comes to manual work.

It’s important to schedule refresher courses annually at minimum so as to maintain employee proficiency concerning health and safety protocols. By continuing such educational efforts regularly, workers become more aware of potential risks present within their working environment and there is a corresponding decline in injury rates stemming from high-risk activities involving handling operations.

Monitoring and Reviewing Risk Assessments

Continuous vigilance and reassessment of risk assessments are vital to keeping a current grasp on the risks associated with manual handling. An annual reevaluation of manual handling risk assessments is advised. Employers must periodically revisit these reviews or in response to any alterations, like shifts in personnel, procedures, or machinery.

Subsequent to any incidents or narrowly avoided mishaps, it’s imperative to reexamine the pertinent risk assessments to ascertain whether there’s a need for additional control measures. Keeping an accurate log of all events related to manual handling promotes both accountability and transparency within an organisation.

By regularly revisiting and refreshing risk assessments, employers can ensure that modifications within the workplace don’t give rise to new dangers linked with manual labor tasks.

Addressing High-Risk Handling Operations

Specialised tactics are essential for maintaining safety and managing high-risk manual handling operations. For such tasks, it is often most prudent to engage professional removal firms that have the necessary equipment and training to safely conduct activities that carry a higher risk level, including those involving dangerous materials or intricate situations where advanced know-how and apparatus are required.

When employing devices like hoists, which can be hazardous for both patients and operators if mishandled, enlisting expert removal companies becomes crucial. Leveraging sophisticated machinery assists in diminishing the potential of harm during these manual handling processes and safeguards worker safety throughout these elevated risk handling endeavours.

Reporting and Investigating Incidents

It is vital to report and scrutinise incidents involving manual handling to deter future occurrences and bolster safety. Any event tied to the moving and handling process must be reported in alignment with the guidelines established by employers. Prompt notification of a supervisor and the recording of details within an accident report are integral aspects of this reporting procedure.

To ensure workplace safety, employers have obligations towards their nursing personnel and other workers when it comes to investigating reported mishaps promptly and taking decisive action designed not just for immediate remedy but also long-term prevention. These interventions should delve into underlying causes while crafting strategies that mitigate chances for similar events going forward.

Employers can significantly minimise risk factors associated with manual handling tasks by advocating transparency alongside a commitment to continuous improvement, ultimately contributing toward lowering instances of injury among employees.

Summary

In summary, understanding and managing manual handling risks are essential for ensuring workplace safety and compliance with legal obligations. By following the TILE approach, conducting thorough risk assessments, implementing control measures, and providing ongoing training and education, employers can significantly reduce the risk of injury. Regular monitoring and reviewing of risk assessments ensure that safety measures remain effective and up-to-date.

Creating a safer working environment requires a commitment to continuous improvement and vigilance. By prioritising the health and safety of workers, employers not only comply with regulations, but also foster a culture of safety and well-being. Let’s work together to reduce manual handling risks and protect our most valuable asset—our workforce.