When handling tiles manually, it’s crucial to assess the risks involved in manual handling tiles. Using the TILE framework—Task, Individual, Load, Environment—helps in identifying and mitigating these risks effectively. This article explains how to use TILE for safe tile handling and emphasises the importance of employing correct manual handling techniques.

Key Takeaways

- The TILE framework—Task, Individual, Load, Environment—provides a comprehensive method for evaluating risks associated with any manual handling activity, promoting employee safety.

- Understanding each element of TILE helps identify hazards and implement measures to mitigate risks, ultimately reducing the occurrence of musculoskeletal injuries.

- Legal obligations under the Manual Handling Operations Regulations require employers to assess and mitigate risks, emphasising the necessity of frameworks like TILE for safe manual handling practices.

What is Manual Handling?

Manual handling refers to any physical activity that involves moving or supporting a load with your body or hands. This can involve lifting, pushing, lowering, carrying, pulling, or transporting a load. A ‘load’ in manual handling does not just apply to an inanimate object; it can also refer to the handling of a person or an animal. Manual handling is a common cause of workplace injuries and illnesses, and it is essential to follow safe manual handling techniques to prevent these injuries.

Safe manual handling techniques are crucial in minimising the risk of injury. These techniques include proper lifting methods, using mechanical aids when necessary, and ensuring that the work environment is conducive to safe handling practices. By adhering to these techniques, employees can significantly reduce the likelihood of sustaining injuries related to manual handling activities.

What is Manual Handling TILE?

Manual handling encompasses any activity that necessitates applying physical effort to lift, drop, shove, haul or transport a load through manual means. Employing the TILE methodology—which stands for Task, Individual, Load and Environment—is vital in pinpointing manual handling hazards linked with these activities. It is designed as an extensive mnemonic to review every aspect of a manual handling task meticulously—ranging from the characteristics of the individual load to the specifics of one’s surroundings—with the goal of recognising and lessening potential risks during any given manual handling job.

The importance of TILE within manual handling operations cannot be overstated. By dissecting each element individually, TILE acts as a cornerstone for safeguarding employees and diminishing injuries associated with manual tasks. This framework isn’t just about guidelines. It advocates for proactive measures towards creating safer work environments, which might include using aids like tile stands.

TILE accounts for numerous critical factors—from how hefty an item may be to ensuring that those performing said tasks are physically equipped—to ascertain safe execution across all aspects involving such operative endeavours.

Breaking Down the TILE Acronym

The acronym TILE represents four critical elements—task, individual, load, and environment—that are essential for a thorough risk assessment associated with manual handling tasks. By analysing each factor separately, both employers and workers can recognise potential hazards linked to manual handling activities and take appropriate steps to reduce those risks.

In assessing the risks tied to a manual handling operation in detail, every part of the TILE framework—the task itself, the individual who performs it, the load being handled, as well as the surrounding environment—is vital. This approach ensures that all aspects of a job are evaluated methodically during a manual handling risk assessment.

Task

Undertaking manual handling tasks involves evaluating the specific movements required, which is an essential element within the ‘Task’ component of TILE. This includes determining whether activities such as lifting, pushing, pulling, or lowering are necessary and acknowledging that each action poses varying levels of risk, requiring distinct safe handling techniques. Recognising what the task entails assists in pinpointing potential dangers, which could involve excessive physical effort to perform a job or working around objects with sharp edges.

When assessing a manual handling assignment’s risks, factors like how long the task takes and how often it includes repetitive actions need to be considered. Delivery drivers regularly contend with high-risk situations due to repetitively performing similar motions related to their role. By identifying these hazards beforehand, one can better prepare to implement safer approaches to manual handling tasks, thereby minimising injury chances.

Individual

The ‘Individual’ component of TILE emphasises the importance of evaluating the person who is undertaking the manual handling task. It’s vital to consider their physical ability, any health conditions they may have, and whether they’ve received previous manual handling training. Essential attributes like age, height, and strength play a significant role in determining if someone can execute the task without harm.

It is essential to continually reassess an individual’s capacity for manual handling tasks as it may evolve due to various reasons, such as changes in health or other factors. For example, adjustments might be necessary when dealing with a pregnant individual compared to others.

Acknowledging and adapting to these variations are key in ensuring that all manual handling tasks are carried out safely and effectively.

Load

The characteristics of the item being manipulated, known as the ‘Load’ component, encompass its weight, dimensions, stability, and any potential hazards it may possess. The likelihood of injury is notably heightened by a load that is heavy or large in size. This risk escalates. If such a load hampers visibility or lacks steadiness.

It’s vital to conduct an in-depth assessment of the properties associated with the load to guarantee secure manual handling practices. Dividing heavier loads into segments that are easier to manage or employing mechanical aids like trolleys can significantly alleviate stress on individuals performing these tasks. Doing so not only enhances safety but also boosts efficiency by curtailing the chances of sustaining injuries from manual handling activities.

Environment

TILE’s ‘Environment’ aspect pertains to the workspace’s physical state in which the manual handling task is executed. Uneven flooring, inadequate lighting, and confined areas are examples of environmental factors that can greatly influence both safety and effectiveness during manual handling operations.

To uphold health and safety standards for safe manual handling, it is crucial to recognise and address potential risks in the environment. Actions such as verifying non-slip floors and providing sufficient illumination help avert mishaps and harm. Maintaining an orderly work area not only boosts securiy, but also augments efficiency across all manual handling processes.

The Importance of TILE in Manual Handling Risk Assessment

Employing the TILE framework is crucial for executing comprehensive risk assessments related to manual handling. This approach aids in pinpointing potential hazards and taking steps to reduce their impact, which serves as a safeguard against employee injuries. A meticulous examination of the task, individual load, and environment account for every vital element associated with manual handling.

Using TILE has been instrumental in diminishing occurrences of musculoskeletal disorders along with other injuries tied to manual handling activities. It offers an organised method for conducting risk assessments, facilitating the recognition of aspects requiring enhancements. When paired with adequate training, this framework plays a key role in fostering both a safer work setting and an ethos dedicated to safety practices.

Understanding LITE in Manual Handling

The LITE framework, an acronym for load, individual, task, and environment, is used in the execution of risk assessments concerning manual handling. This method bears resemblance to TILE but equally underscores the critical evaluation of each element as a means to mitigate injury risks. By implementing LITE’s tenets, employers are empowered to forge work settings that prioritise safety.

By improving elements such as lighting and flooring within the workplace setting can significantly augment safety pertaining to manual handling activities. The LITE strategy offers a thorough technique for conducting risk assessments similar to its counterpart TILE. By accounting for all vital aspects during this process, it supports in averting injuries related to manual handling while fostering secure operational protocols.

Expanding to TILEO: Including Other Factors

By introducing ‘Other Factors’ into the TILE framework, forming TILEOa more substantial consideration is given to aspects that can greatly influence the safety and efficacy of manual handling tasks. Such factors may involve requirements for additional apparatus or particular protective protocols which are vital under certain conditions.

Taking these ‘Other Factors’ into account markedly diminishes potential hazards. The integration of TILEO within risk assessments guarantees an all-encompassing analysis that fosters safer and improved efficiency in manual handling operations.

Legal Obligations and Manual Handling Legislation

The regulatory structure for manual handling activities aims to safeguard workers from potential injuries. Established in 1992 and later modified in 2002, the Manual Handling Operations Regulations mandate that employers evaluate the risks linked to manual handling tasks and take action to reduce them.

It is an employer’s responsibility to shield their workforce from dangers related to manual handling, just as it is incumbent upon employees themselves to exercise due care towards their own safety and that of others. This duty highlights the significance of applying methods such as TILE or LITE when performing comprehensive risk assessments with a view toward promoting safe practices in manual operations.

Safe Manual Handling Techniques

It is crucial to adhere to proper manual handling methods in order to avoid injuries and maintain safety. By regularly implementing the right techniques for manual handling, coupled with offering adequate training, it’s possible to substantially reduce the likelihood of sustaining injuries related to manual handling.

Below, you will find an elaboration on these specific techniques.

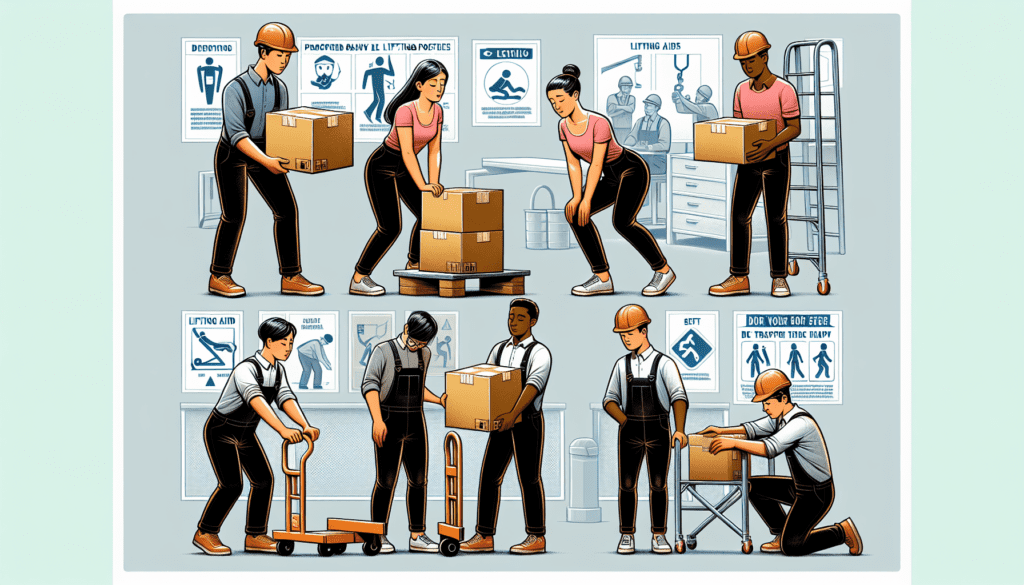

Proper Lifting Techniques

Utilising proper lifting techniques is crucial for reducing the possibility of injuries when engaging in manual handling tasks. Embracing the item being lifted close to one’s body enhances both stability and strength during the lift. If a long lift is necessary, placing the object on a bench or table can provide an opportunity to regain grip strength.

Ensuring that the load’s heaviest portion remains closest to your body Contributes to maintaining balance and enhancing lifting power. Employing these strategies ensures safe manual handling practices are observed, thereby helping to avoid injuries.

Use of Mechanical Aids

The use of mechanical aids greatly alleviates the physical effort involved in manual handling, especially when dealing with heavy loads. Trolleys and hoists are frequently employed to enhance safety and efficiency during these tasks. It is vital within the TILEO framework to assess both the suitability and effectiveness of such devices.

Introducing mechanical aids mitigates injury risks while boosting productivity levels. They provide substantial support by not only securely moving heavy loads but also by reducing the extent of physical effort necessary for manual handling activities.

Training and Education

Education and training play a crucial role in ensuring safe manual handling techniques are practiced consistently. Keeping workers abreast of the most recent safety protocols and effective handling methods is achieved through regular training sessions.

By committing to robust manual handling training, businesses can decrease the frequency of workplace injuries, thus fostering a more secure working atmosphere. Employees who have been thoroughly trained possess a heightened awareness that enables them to identify potential hazards and take steps to prevent them.

Common Injuries from Manual Handling

Tasks involving manual handling are a significant source of workplace injuries that do not result in fatalities. These include strains and sprains, as well as musculoskeletal disorders, which can arise from repetitive movements or improper lifting techniques. Overlooking the principles encapsulated by TILE (task, individual, load, environment) may have grave repercussions for employees.

In UK workplaces alone, incorrect practices in manual handling contribute to about 21% of non-fatal injuries on the job each year. This amounts to more than 10,000 cases annually. Such figures underscore the necessity of employing safe manual handling methods alongside comprehensive risk assessments to prevent such incidents.

Manual Handling Tasks

Manual handling tasks are any tasks or activities in the workplace that involve manual handling. These tasks can include lifting, pushing, carrying, lowering, pulling, transporting, assembling, cleaning, packing, making deliveries, typing, operating machinery or equipment, and handling or restraining animals. Manual handling tasks occur in a large variety of workplaces, and it is essential to assess the risks associated with these tasks to prevent injuries and illnesses.

Each manual handling task presents unique challenges and risks. For instance, lifting heavy boxes in a warehouse requires different considerations compared to handling animals in a veterinary clinic. Conducting a thorough manual handling risk assessment for each task helps identify potential hazards and implement measures to mitigate them. This proactive approach ensures that all manual handling activities are performed safely and efficiently.

Implementing TILE in the Workplace

Implementing TILE in the workplace is crucial to ensure safe manual handling practices. TILE stands for Task, Individual, Load, and Environment, and it is used to assess the risks associated with manual handling tasks. By considering these four factors, employers and employees can identify potential hazards and take steps to reduce or remove them.

To effectively implement TILE, employers should develop comprehensive manual handling procedures that incorporate the TILE framework. This includes providing manual handling training to employees, conducting regular risk assessments, and ensuring that the work environment is safe and conducive to manual handling activities. By integrating TILE into daily operations, employers can significantly reduce the risk of manual handling injuries and illnesses, creating a safer and more productive workplace.

In summary, the TILE framework is an invaluable tool for promoting safe manual handling practices. By evaluating the task, individual, load, and environment, employers can identify potential hazards and implement measures to mitigate them. This comprehensive approach not only enhances safety but also fosters a culture of health and safety within the workplace.

Practical Tips for Reducing Manual Handling Risks

Planning tasks meticulously is key in pinpointing risk factors, which in turn contributes to more secure manual handling practices. The utilisation of suitable personal protective equipment (PPE) is vital for ensuring the safety of those involved in manual handling. Keeping a work environment tidy and conducting frequent evaluations can help prevent dangers, thus guaranteeing the safe execution of manual handling.

Employers must promote transparent dialogue concerning possible risks and offer ongoing updates on training. By nurturing an atmosphere where safety and alertness are prioritised, there’s a substantial decrease in the risks associated with manual handling.

Summary

In summary, the TILE framework is essential for conducting effective manual handling risk assessments. By evaluating the task, individual, load, and environment, TILE helps identify potential hazards and implement measures to mitigate them. This comprehensive approach significantly reduces the risk of manual handling injuries and promotes a safer workplace.

Understanding and applying the principles of TILE, LITE, and TILEO can make a significant difference in manual handling safety. By investing in proper training and regularly updating safety practices, employers can create a safer and more efficient work environment. Remember, safe manual handling is not just a set of guidelines—it’s a commitment to protecting the well-being of everyone in the workplace.

Frequently Asked Questions

What does TILE stand for in manual handling?

TILE stands for Task, Individual, Load, and Environment, which are key factors in evaluating manual handling risks and ensuring safety.

How does TILE differ from LITE?

TILE emphasises an analysis of Task, Individual, Load, and Environment components in a specific order while LITE puts the emphasis on Load, Individual, Task, and Environment.

When deciding between them for a risk assessment, it’s essential to consider the particular context of each situation involving task, individual load and environment.

Why is manual handling training important?

Manual handling training is essential as it equips employees with safe handling techniques, minimises injury risks, and ensures adherence to health and safety regulations.

Prioritising this training fosters a safer workplace environment.

What are common injuries associated with manual handling?

Common injuries associated with manual handling include musculoskeletal disorders, strains, and sprains, typically arising from improper lifting techniques or repetitive movements.

It is crucial to employ correct methods to minimise the risk of such injuries.

What legal obligations do employers have regarding manual handling?

Employers must assess risks associated with manual handling and implement measures to protect employees, as mandated by the Manual Handling Operations Regulations.

Failure to comply can lead to legal consequences and jeopardise employee safety.