- Key Takeaways

- Understanding Safe Moving and Handling

- Key Principles for Safe Moving and Handling

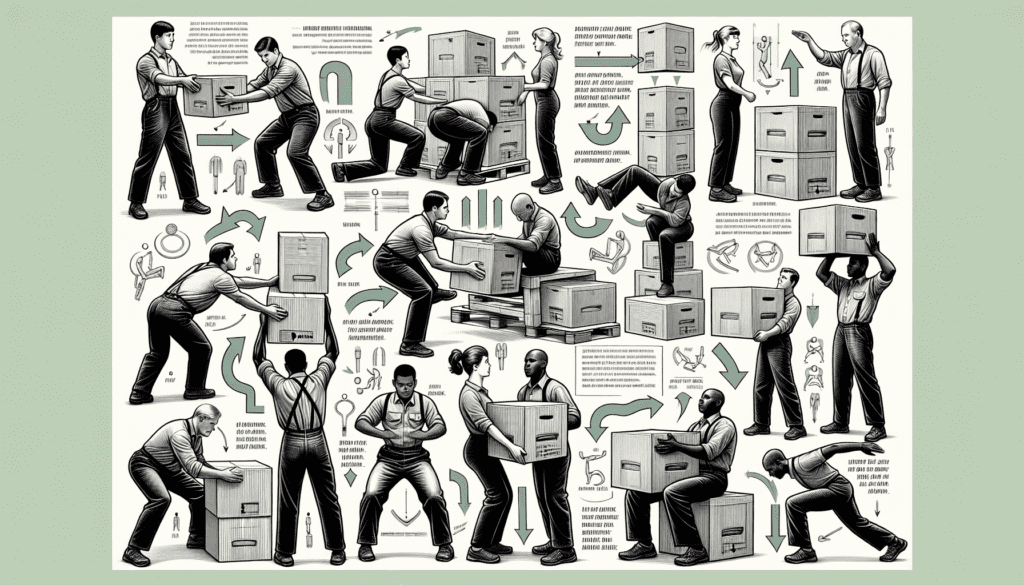

- Techniques for Safe Moving and Handling

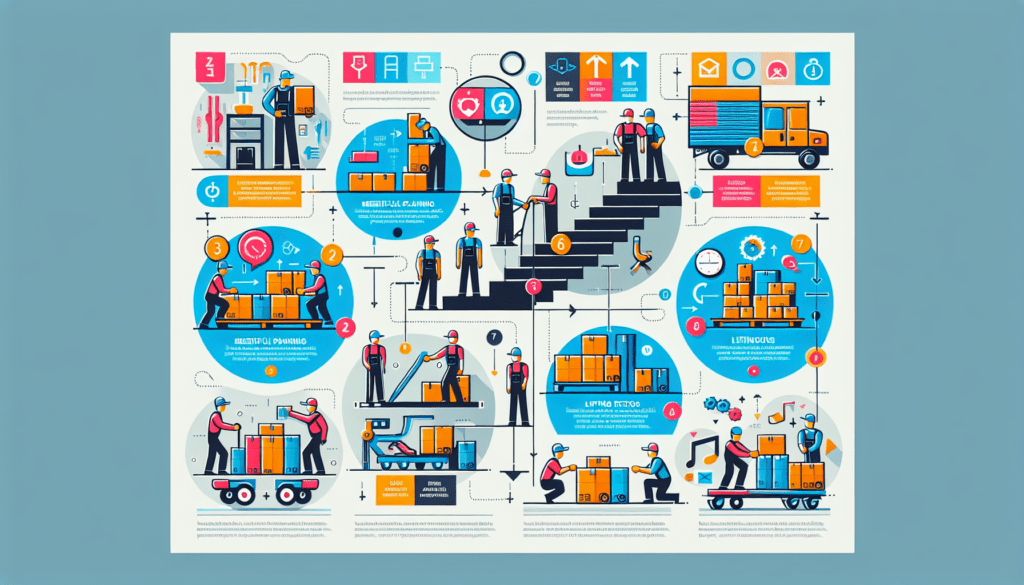

- Safe Moving and Handling Procedures

- The Role of Manual Handling Regulations

- Importance of Training in Safe Moving and Handling

- Conducting Effective Risk Assessments

- Using Personal Protective Equipment (PPE)

- Ensuring Compliance with Safety Guidelines

- Summary

- Frequently Asked Questions

Safe moving and handling are critical skills, especially in healthcare settings, to prevent injuries to both staff and patients. This article will explain the principles of safe moving and handling, covering essential guidelines like risk assessment, proper planning, and use of suitable equipment. Understanding these principles helps ensure a safer working environment for everyone.

Key Takeaways

- Proper training in safe moving and handling can significantly reduce the risk of injuries in healthcare settings.

- Key principles include conducting thorough risk assessments, proper planning, and using suitable equipment to enhance safety.

- Regular training and assessments, along with compliance with safety guidelines, are essential for maintaining a safe working environment for caregivers and patients.

Understanding Safe Moving and Handling

The act of manual handling within care settings involves various physical manoeuvres, such as lifting and transferring individuals with restricted mobility. It encompasses the management and transportation of patients as well as items in healthcare and social care environments, playing a vital role in maintaining the health and welfare of both staff members and those under their care. Incorrect execution during these manual handling activities can result not only in discomfort but is also responsible for a substantial number of back injuries annually—exceeding 300,000 cases related to different forms of manual tasks.

Educating employees on safe-moving principles significantly mitigates these hazards. Adequate training can decrease workplace injury occurrences along with associated financial burdens stemming from absence due to illness or injury, regulatory penalties, or legal action. Adherence to safety guidelines promotes protection and efficiency among healthcare workers when undertaking lifting or relocation duties.

Recognising varied elements involved in these processes—including people needing assistance, objects that must be handled safely, and equipment—is crucially important for operational success. Factors like appropriate equipment usage coupled with targeted safety instruction greatly affect how effectively such movements are carried out. The application of established procedures regarding safe moving enhances occupational security conditions overall while simultaneously guarding against potential harm.

Key Principles for Safe Moving and Handling

In healthcare environments, it’s essential to implement safe moving and handling protocols to minimise the likelihood of injuries. The adherence to five core principles of safe manual handling is pivotal in diminishing these hazards. These central elements consist of comprehensive risk assessments, meticulous planning, and the deployment of appropriate equipment.

To delve deeper into this subject matter, we will examine these critical components with greater specificity.

Risk Assessment

It is imperative to perform risk assessments in order to discern potential hazards and adopt control measures, thus averting adverse outcomes. Before engaging in any moving and handling activities, evaluating the risks involved along with the environmental context is crucial. This evaluation aims at identifying possible dangers and spotlighting areas that need intervention for injury prevention.

Taking into account individual needs as well as potential dangers is critical before producing or handling individuals. For a patient’s initial move, it is essential that a risk assessment be conducted to ascertain the most suitable methods tailored to their unique requirements.

Such preventive tactics not only diminish the likelihood of harm but also uphold an approach centered on personal care which prioritises both patients’ and caregivers’ welfare during handling tasks.

Proper Planning

Ensuring safe moving requires meticulous preparation of the handling activity. It is vital to prepare the area by clearing out any obstructions and verifying there is sufficient space available prior to lifting a load. Such precautions greatly increase safety throughout the moving and handling process.

Securing all required equipment and ensuring clear access are imperative measures in planning. Adherence to these strategies ensures that activities involving moving and handling proceed without incident, diminishing the likelihood of injuries. Observing these safe working practices contributes to establishing a more secure and efficient environment for all participants involved in the handling process.

Use of Suitable Equipment

It is crucial to employ the right lifting equipment for safe moving and handling operations. Safety during transfers can be greatly improved by utilising aids like lift gear and slide sheets, which are designed to mitigate injury risks linked with manual handling.

Choosing suitable equipment for moving and handling duties plays a pivotal role in maintaining safety while enhancing productivity. Adhering to the instructions provided by the manufacturers of this equipment, along with acquiring any additional training required, promotes proper usage. Adopting such measures guarantees that tasks involving moving and handling are conducted securely and competently.

Techniques for Safe Moving and Handling

It is essential to utilise proper techniques when performing moving and handling tasks in order to avoid injuries. These methods emphasise the importance of keeping a good posture, securing a stable grip and position, and carrying out actions with smoothness and balance.

Now, let’s explore these techniques more comprehensively.

Maintaining Good Posture

Preserving a proper posture is crucial when performing manual handling tasks to avoid unnecessary strain. To achieve this, one should keep their back upright and bend from the hips and knees instead of bending at the back. This approach maintains a neutral spinal position, diminishing the likelihood of experiencing discomfort or sustaining injuries.

Engaging leg muscles rather than relying on your back while lifting, coupled with holding items close to your waist level, lessens tension on the body and boosts control over the load. It’s important as well to prevent twisting movements by keeping shoulders aligned with hips during any moving and handling activities, which reduces injury risks.

Adhering consistently to these guidelines will support maintaining correct posture throughout various manual handling responsibilities and help in avoiding potential injuries associated with such tasks.

Secure Grip and Stable Position

Securing a firm hold is vital for the safety of both the handler and patient during safe moving and handling, as it allows for controlled maneuvering of the load while ensuring comfort. By strengthening one’s grip on an object, the risks associated with accidental drops are significantly reduced, which is crucial to prevent harm.

Adopting a balanced posture is integral when managing loads in any handling task. Achieving stability can be done by positioning feet apart at shoulder width and ensuring they are comfortably placed to sustain balance throughout the movement. This technique assures that actions involved in transferring loads are executed without incident, thereby preventing injuries and promoting overall safety.

Smooth Movements and Balance

Ensuring balance and smooth actions are essential elements in the practice of safe moving and handling. Positioning feet apart at shoulder width contributes to improved stability while undertaking handling duties. A secure stance can be achieved by placing one foot slightly ahead of the other, aiding in preserving equilibrium and minimising strain.

Upholding a straight neck and keeping the head erect during load engagement lessens injury risk. To safeguard against spinal stress throughout the handling process, it is advisable to steer clear of any twisting motions while maintaining proper posture.

Adhering to these fundamental tenets facilitates efficient execution of tasks related to moving and handling, all while prioritising safety.

Safe Moving and Handling Procedures

Ensuring safety and efficiency in moving and handling tasks is imperative, which requires adherence to set protocols. The upkeep of lifting equipment and handling equipment is vital for the safe execution of such activities. Neglecting maintenance can heighten injury risks.

During the execution of these tasks, clear communication between team members is paramount to guarantee a unified approach. Control measures already in place should be recorded during assessments, along with additional steps required for risk reduction.

To facilitate this process effectively, an action plan must be crafted that designates necessary actions as well as assigns responsibility for their implementation. This methodical strategy guarantees that all tasks related to moving and handling are conducted with utmost safety and proficiency.

The Role of Manual Handling Regulations

Workplace accidents frequently stem from manual handling incidents, highlighting the critical need for regulatory measures. To minimise the risk of injury related to hazardous manual handling tasks, employers are legally obligated to lessen it as much as is feasible. This responsibility encompasses equipping workers with suitable personal protective equipment (PPE) to protect against injuries.

It is incumbent upon employers to furnish their workforce with the necessary information, guidance, and training geared toward adherence to safe practices in manual handling. To bypass the necessity for manual handling operations wherever possible, introducing mechanical aids or revamping workplace procedures plays a pivotal role.

By adhering to these prescribed norms and regulations regarding manual handling activities within their jurisdiction, businesses can foster a safer work environment while simultaneously curtailing risks associated with injuries.

Importance of Training in Safe Moving and Handling

It is crucial to provide healthcare workers with ongoing education in safe moving and handling procedures to uphold stringent safety protocols. In the healthcare sector, a substantial number of occupational illnesses are due to injuries incurred from incorrect manual handling techniques. To reduce such risks and safeguard staff from harm, training in these practices is essential.

To ensure effectiveness, this training must be customised to reflect the particular risks and methods pertinent to the roles of employees. Employees should undergo refresher courses on safe moving and handling every one or two years so that these important safety measures remain at the forefront of their daily activities. Employer-provided comprehensive instruction guarantees that tasks involving movement and handling are executed both securely and proficiently.

Conducting Effective Risk Assessments

It is essential to consistently perform risk assessments for manual handling activities in order to stay abreast of changing conditions and maintain a safe work environment. Before undertaking any manual handling, employers should carry out these assessments to pinpoint potential hazards and ascertain the most appropriate techniques for safe handling.

Employing instruments such as the MAC tool, V-MAC tool, ART tool, and Push/Pull tool can provide comprehensive evaluations that help mitigate possible risks associated with manual handling. To guarantee continuous protection against injuries or accidents, it’s important to revisit and update risk assessments on a regular basis or whenever there are alterations in working practices or environments. Adopting this vigilant strategy ensures the preservation of health and safety standards within the workplace.

Using Personal Protective Equipment (PPE)

Essential for reducing the risks associated with hazards that arise from manual handling tasks, personal protective equipment (PPE) must be employed. This includes items such as gloves, steel toe cap boots, eye protection, and lifting belts specifically designed for manual handling activities.

To safeguard workers against potential harm while performing moving and handling duties, it is imperative to utilise the correct PPE. It’s incumbent upon employers to supply the requisite personal protective equipment and provide adequate training on its proper application. Adhering to this protocol promotes a more secure workplace by diminishing the likelihood of injuries related to equipment handling.

Ensuring Compliance with Safety Guidelines

Ensuring the operational safety and adherence to regulations for moving equipment necessitates consistent upkeep and checks. In healthcare establishments, a robust culture of safety encourages transparent incident reporting, which fosters ongoing enhancement of safety protocols.

Involving patients in conversations regarding their preferences when it comes to lifting and moving not only upholds their comfort and respect, but also aids in maintaining compliance with established safety standards as well as the manufacturer’s instructions for equipment use. Adherence to these directives is essential in preventing significant injuries related to manual handling tasks and supports healthcare workers in creating a more secure workplace environment.

Summary

In summary, it is crucial to grasp and implement the principles of safe moving and handling to avoid injuries and guarantee a secure work setting. Healthcare workers can carry out moving and handling activities safely and competently by performing comprehensive risk assessments, planning adequately, utilising appropriate equipment, and following proper techniques.

The importance of training in tandem with adhering to safety regulations cannot be overstated in upholding elevated standards of safety. Adherence to these guidelines ensures that both healthcare providers and patients operate within an environment that is not only safer but also more productive.